Let the world fall in love with Banghong Zhongchuang, and let Chinese drilling tools go to the world!

View the official account

φ75 three-wing diamond coreless drill

所属分类:

φ75 three-wing diamond coreless drill

关键词:

Specifications

Scope of application

咨询热线:

- Product Description

- Instructions for use

- Applications

- Product parameters

-

- Commodity name: φ75 three-wing diamond coreless drill

- Specifications: φ75

- Scope of application: The diamond drill bits produced by our company are widely used in various regions at home and abroad. The main domestic application areas are: China Coal Group, Longmei Group, Shenmei Group, Fengfeng Coal Industry, Kailuan Coal Industry, Lu'an Coal Indust

φ75 three-wing diamond coreless drill

Diamond drill

Alias: Diamond Bits, Diamond Compact Disc Bits, PDC Bits

Product parameters:Product ParametersDiamond Compact (PDC) Bit Series

Diamond Compact Disc (PDC) is a special superhard material synthesized by synthetic diamond and cemented carbide at one time under high temperature conditions. It not only has the advantages of high diamond hardness and wear resistance, but also has the impact resistance of cemented carbide. It has the characteristics of strong strength and large cutting edge. Using it as the blade of the drill bit can greatly improve the work efficiency of the drill bit. It is an ideal drill bit for drilling into medium and hard rock layers.

Strength distinction:

The strength of the diamond composite drill is mainly determined by the strength of the diamond composite. At present, the strength of the diamond composite drill is mainly divided into three types: ordinary, reinforced, and high-strength; the diamond composite is mainly divided into 1304 and 1308. Types, 1304 and 1308 refer to the diameter and thickness of the composite sheet. The basic types we use are: ordinary type, reinforced type and high-strength type; the ordinary type is 1304 flat composite sheet, and the reinforced type is 1304 spherical composite sheet and 1308 plane. Composite sheet, high-strength type is 1308 spherical composite sheet.

The high-strength diamond blade blade adopts the newly developed spherical diamond blade, which is characterized by fast drilling speed and strong impact resistance. When the drill bit is drilling, the lip is used to scrape the rock in the normal and uniform formation. The protruding part can prevent the drill bit from cutting a large amount of footage instantaneously when it encounters a gap during the drilling process, which greatly reduces the accidental damage of the drill bit and improves the drilling ability to deal with complex rock formations. into the level. **Adapted to the rock formation and drilling schedule parameters as shown in the table below:Adapt to the rock formation parameter table:

line number Type Adapt to rock formations

1

Ordinary PDC drill

Soft to medium hard rock with F<10

2

Reinforced PDC bits

Medium hard rock with F=10-12 3

High strength PDC drill

Hard rock with F<18

Application Field:

At present, the application fields of diamond compact bits are relatively wide. The diamond bits produced by our company are all over the country in coalfields, oil drilling, geological exploration, water conservancy and hydropower, railways, highways, tunnel construction and other industries.

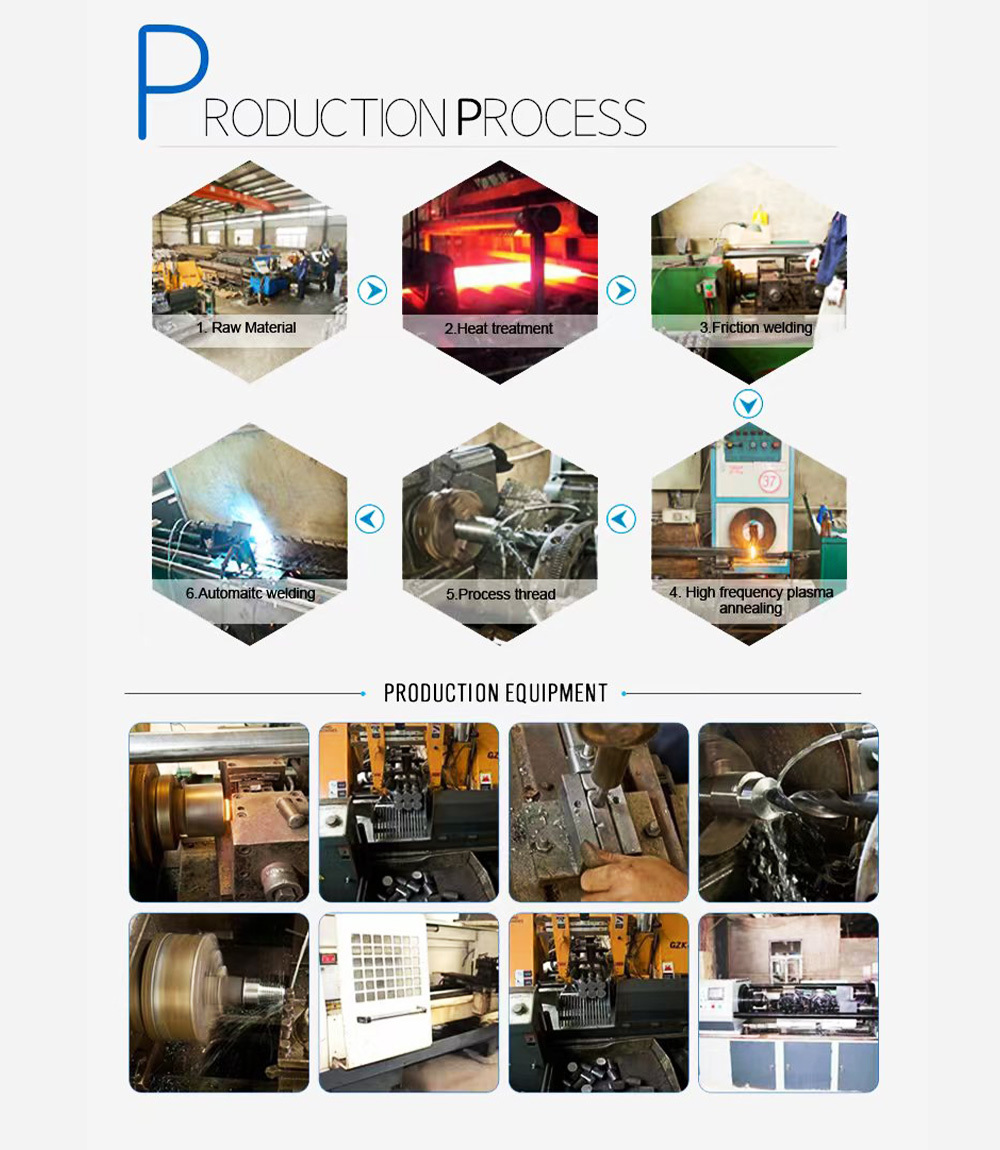

Product Advantage:The diamond composite drill bits produced by our company are made of high-quality steel forging and pressing, and are processed by vacuum automatic heat treatment equipment to increase the mechanical properties. The ordinary type adopts domestic high-quality composite blades as the blade, and the super-strong type adopts the blade produced by GE Company in the United States. According to the different geological conditions, the corresponding quality grade can be selected, which can achieve higher product cost performance and achieve economic indicators of energy saving and high efficiency.

The diamond drill bits produced by our company are all over the country in coal field, oil drilling, geological exploration, water conservancy and hydropower, railway and highway, tunnel construction and other industries. The two-wing PDC anchor bit (half-piece standard type) is suitable for rock formations below grade 8. Under the same rock formation conditions, the drilling life is 10-30 times that of ordinary alloy drill bits, and the efficiency is increased by at least 60%. Labor intensity, saving working hours. The key raw materials of the two-wing PDC anchor bit (half-piece reinforced type) blade are produced by GE Company in the United States. Its diamond content is 1.5 times that of ordinary drill bits. It has excellent wear resistance, significantly improved efficiency, and reduced overall cost. It is suitable for medium-hardness below grade 12. rock formations.

The high-strength diamond drill blade adopts the newly developed spherical diamond blade, which is characterized by fast drilling speed and strong impact resistance. When the drill bit is drilling, the lip is used to scrape the rock in the normal and uniform formation. The protruding part can prevent the drill bit from cutting a large amount of footage instantaneously when it encounters a gap during the drilling process, which greatly reduces the accidental damage of the drill bit and improves the drilling ability to deal with complex rock formations. into the level.

-

Diamond Compact Disc (PDC) is a special superhard material synthesized by synthetic diamond and cemented carbide at one time under high temperature conditions. It not only has the advantages of high diamond hardness and wear resistance, but also has the impact resistance of cemented carbide. It has the characteristics of strong strength and large cutting edge. Using it as the blade of the drill bit can greatly improve the working efficiency of the drill bit. It is an ideal drill bit for drilling medium and hard rock layers.

-

The diamond drill bits produced by our company are widely used in various regions at home and abroad. The main domestic application areas are: China Coal Group, Longmei Group, Shenmei Group, Fengfeng Coal Industry, Kailuan Coal Industry, Lu'an Coal Industry, Yangmei Group, Jinmei Group, Xishan Coal and Electricity, Fenxi Coal Industry, Datun Coal Industry, Xinji Energy, etc.; the main use areas in foreign countries: Russia, Australia, Southeast Asia and Northern Europe.

-

Suggested parameter table for drilling regulations of diamond compact (PDC) bits:

line number Specification mm Drilling schedule parameters Drilling pressure (Kg) Speed (rpm) Pump volume (1/min) 1

Ф28

300—700

300—350

150—200

2

Ф30

300—700

300—350

150—200

3

Φ32

300—700

300—350

150—200

4

Φ48

300—700

300—350

120—160

5

Φ56

320—800

250—350

130—180

6

Φ75

480—1200

200—300

150—200

7

Φ94

640—1600

150—250

200—250

8

Φ110

880—2200

120—200

200—300

9

Φ152

1500—3000

100—200

500—850

10

Φ190

1800—4000

100—200

600—1200

11

Φ230

2200—4500

100—200

750—1400

12

Φ270

2400-5000

100—200

1000-1500

Related Products

Product message

Shandong Banghong Zhongchuang Intelligent Equipment Co., Ltd.

Address: West Huamei Road, Linqing Youth Office, Liaocheng City, Shandong Province

copyright © 2022 Shandong Banghong Zhongchuang Intelligent Equipment Co., Ltd.

+86-13508921191

+86-13508921191