Let the world fall in love with Banghong Zhongchuang, and let Chinese drilling tools go to the world!

View the official account

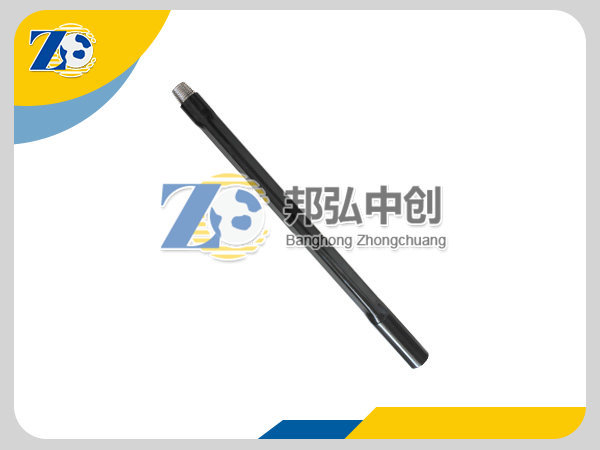

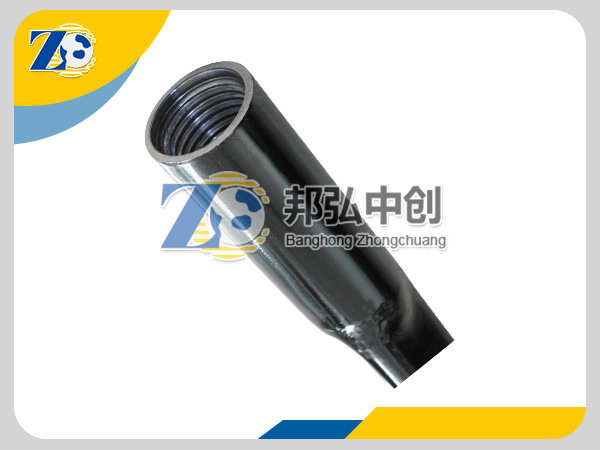

Φ50Triangular drill pipe(friction welding)

所属分类:

Φ50Triangular drill pipe(friction welding)

关键词:

Specifications

Material code

Connection method

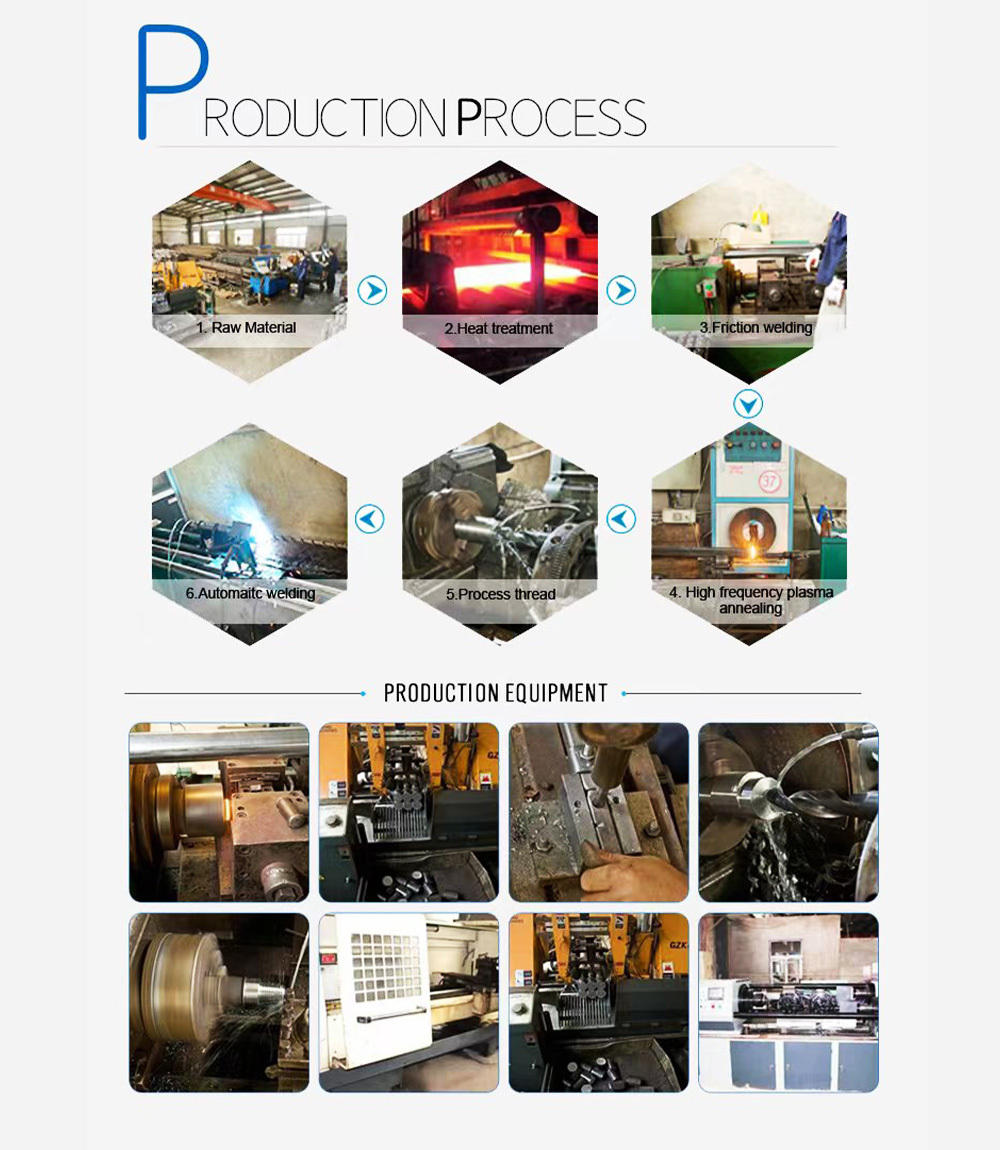

Production Process

Scope of application

咨询热线:

- Product Description

- Instructions for use

- Applications

- Product parameters

-

- Commodity name: Φ50Triangular drill pipe(friction welding)

- Specifications: Φ50

- Material code: -

- Connection method: -

- Production Process: -

- Scope of application: It is widely used in drilling under the geological conditions of coal seam and near coal seam, water exploration and gas discharge drilling construction in coal mines, and can also be used in geophysical prospecting and water conservancy construction proj

Φ50Triangular drill pipe(friction welding)

Alias:Triangular drill pipe, anti-slump drill pipe, anti-lock drill pipe, triangular pyramid drill pipe.

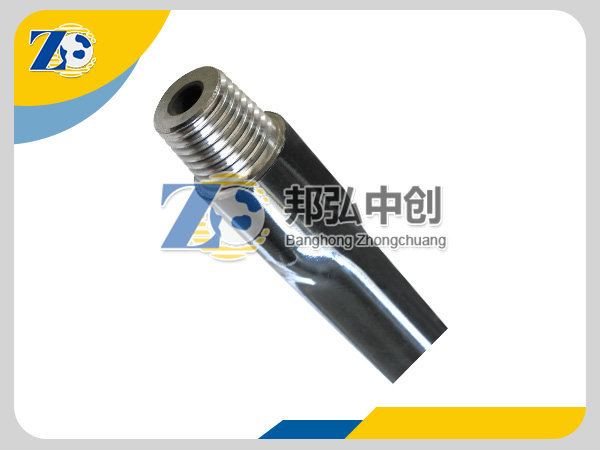

Three-edged drill pipe The three-edged drill pipe for coal mine roadway drilling is made of a three-edged arc steel pipe with a tapered transition as the drill pipe body, and is friction welded with the drill pipe joints in the form of threads or in the form of triangle, square, and hexagon. Completed drill pipe for coal mine drilling. The friction welding process is mainly used, the rod body is a special steel pipe for geological alloys, and the drill pipe joint is a medium carbon alloy structural steel.

Product Parameters

Length:Ф34mm、Ф42mm、Ф50mm、Ф63.5mm、Ф73mm、Ф89mm

Diameter:Ф34mm、Ф42mm、Ф50mm、Ф63.5mm、Ф73mm、Ф89mmSpec

(mm)Connection method

Connection Type

Recommended drilling depth

Torque

(N.M)Diameter

Length

Φ50

800--1500

Tapered thread

Female and female screw connection

50--100m

3500

Φ63

800--1500

Tapered thread

Female and female screw connection

50--120m

5200

Φ73

800--1500

Tapered thread

Female and female screw connection

50--180m

6500

Φ73

800--1500

High pressure thread sea

Female and female screw connection

50--180m

6500

Φ73

800--1500

Triangular plug

Four-way connection

50--250m

7500

Button:connection type: The square connection, the hexagonal connection and the threaded connection are most used in the use of the taper thread connection.

Cone Buckle

Diametermm

taper ratio

pitchmm

Large diametemm

Small diametemmmm

Ф34.00

1:5

4.233

Φ27

Φ20.00

Φ42.00

1:8

5.08

Φ34

Φ29.60

Φ50.00

1:8

5.08

Φ41.5

Φ36.75

Φ63.50

1:6

5

Φ50.5

Φ71.30

Φ73.00

1:6

5

Φ50.5

Φ41.30

Φ73.00

1:4

5.08

Φ59.5

Φ44.50

Φ89.00

1:6

6.35

Φ75

Φ64.10

Flat buckle

Ф34.00

/

6

T28

Φ25.00

Φ42.00

/

6.35

T33

Φ30.00

Φ50.00

/

6.35

T42

Φ39.00

Φ63.50

/

6.35

T54

Φ51.00

Φ73.00

/

8

T63

Φ59.00

Φ89

/

8

T79

Φ75

Product Process

Welding process:It is mainly divided into friction welding type of joints at both ends of the rod body, integral friction welding type and milling pin type of thick-walled steel pipe body. The friction welding type is the most widely used and cost-effective product, and is widely used in the drilling of soft coal seams. The process of the body milling type is friction welding at one end of the male joint. Compared with the friction welded products of the same diameter formed steel pipe, the body milling type triangular drill pipe has a 1-2 times increase in the wall thickness of the drill pipe, and has higher torque and comprehensive Mechanical behavior

Product material:It can be divided into two types, one is 45Mn2 triangular steel pipe welding 42Crmoa joint material, both ends adopt friction welding process. The other is 45Mn2 perforated round steel integrally milled and welded male head 42Crmoa material, the male buckle is friction welded, and the female buckle is directly threaded on the perforated round steel.

Product UsageIt is widely used in drilling under the geological conditions of coal seam and near coal seam, water exploration and gas discharge drilling construction in coal mines, and can also be used in geophysical prospecting and water conservancy construction projects, such as anchoring and drilling construction.

Product ApplicationWhen drilling soft coal seams, the drilling pressure should be small, and the drilling method of air slag discharge has the best effect. Equipped with the light orifice dust suppression device produced by our company, the ideal drilling and hole forming effect can be achieved. The flushing drilling method is easy to cause mud blockage in the hole, and the phenomenon of twisting and breaking of the drill pipe, which affects the drilling of the drill pipe and increases the probability of hole collapse and sticking. However, compared with the cylindrical drill pipe , still has high performance and pore-forming advantages. The diameter difference between the drill bit and the drill pipe should be 10-15mm. If the diameter difference is too large, the effect of the triangular drill pipe on the hole wall will be reduced. The three-edged drill pipe solves a series of problems such as hole collapse, sticking, and locking that are easy to occur in deep hole drilling in soft coal seams; these successful experiences we have accumulated and formed must be explained to customers in place, and professional knowledge can increase customers' understanding of us recognition, increase the probability of transaction.

Product Advantage

According to different geological conditions, we have designed and produced several series of triangular drill pipe products of different types and functions to meet the individual needs of different customers. During the drilling process, three semicircular gaps are formed between the drill pipe and the borehole wall, which expands the channel for dust and gas removal, so that the gas and pulverized coal can be discharged smoothly and avoid stuck pipe accidents. The three smooth surfaces of the edge drill pipe are rotated and greasy, which can solidify the hole wall and reduce the occurrence of hole collapse in the soft coal seam; improve the drilling construction efficiency and porosity rate, and reduce the probability of drilling tool locking and drill pipe breakage and loss. The cost of drilling construction is reduced, and the economic benefit of drilling construction is significantly improved. The three-edged drill pipe series products are reasonable in design, safe and reliable, and are ideal products for deep hole drilling construction in complex geological structures such as soft and soft geology, coal-rock mixture, etc.

-

Product Advantage

According to different geological conditions, we have designed and produced several series of triangular drill pipe products of different types and functions to meet the individual needs of different customers. During the drilling process, three semicircular gaps are formed between the drill pipe and the borehole wall, which expands the channel for dust and gas removal, so that the gas and pulverized coal can be discharged smoothly and avoid stuck pipe accidents. The three smooth surfaces of the edge drill pipe are rotated and greasy, which can solidify the hole wall and reduce the occurrence of hole collapse in the soft coal seam; improve the drilling construction efficiency and porosity rate, and reduce the probability of drilling tool locking and drill pipe breakage and loss. The cost of drilling construction is reduced, and the economic benefit of drilling construction is significantly improved. The three-edged drill pipe series products are reasonable in design, safe and reliable, and are ideal products for deep hole drilling construction in complex geological structures such as soft and soft geology, coal-rock mixture, etc.

-

Product Application

When drilling soft coal seams, the drilling pressure should be small, and the drilling method of air slag discharge has the best effect. Equipped with the light orifice dust suppression device produced by our company, the ideal drilling and hole forming effect can be achieved. The flushing drilling method is easy to cause mud blockage in the hole, and the phenomenon of twisting and breaking of the drill pipe, which affects the drilling of the drill pipe and increases the probability of hole collapse and sticking. However, compared with the cylindrical drill pipe , still has high performance and pore-forming advantages. The diameter difference between the drill bit and the drill pipe should be 10-15mm. If the diameter difference is too large, the effect of the triangular drill pipe on the hole wall will be reduced. The three-edged drill pipe solves a series of problems such as hole collapse, sticking, and locking that are easy to occur in deep hole drilling in soft coal seams; these successful experiences we have accumulated and formed must be explained to customers in place, and professional knowledge can increase customers' understanding of us recognition, increase the probability of transaction.

-

Num

Category

Product nam

Alias

Spec

Model

Weight(KG)

Craft

94

Geoalloy Drill Pipes

Geoalloy drill pipe

Round drill pipe

Outer flat drill pipe

Imitation British drill pipe

Friction Welded Drill Pipe

Water drill pipe

φ50*0.5M

DZ50Flat buckle

4.26

Friction welding

95

Geoalloy drill pipe

φ50*0.79M

DZ50Taper

6.00

Friction welding at both ends

96

Geoalloy drill pipe

φ50*0.79M

45#Taper

6.00

Friction welding at both ends

97

Geoalloy drill pipe

φ50*0.8M

DZ50Taper

6.20

Friction welding at both ends

98

Geoalloy drill pipe

φ50*0.8M

45#Taper

6.20

Friction welding at both ends

99

Geoalloy drill pipe

φ50*0.89M

DZ50Flat buckle

6.00

Two inner wires

100

Geoalloy drill pipe

φ50*0.89M

45#Flat buckle

6.00

Two inner wires

101

Geoalloy drill pipe

φ50*1.0M

45#Flat buckle

6.90

Two inner wires

102

Geoalloy drill pipe

φ50*1.0M

DZ50Flat buckle

6.90

Two inner wires

103

Geoalloy drill pipe

φ50*1.0M

DZ50Taper

8.00

Friction welding at both ends

104

Geoalloy drill pipe

φ50*1.0M

45#Taper

8.00

Friction welding at both ends

105

Geoalloy drill pipe

φ50*1.39M

45#Flat buckle

9.50

Two inner wires

106

Geoalloy drill pipe

φ50*1.39M

DZ50Flat buckle

9.50

Two inner wires

107

Geoalloy drill pipe

φ50*1.5M

45#Flat buckle

10.50

Two inner wires

108

Geoalloy drill pipe

φ50*1.5MM

DZ50Flat buckle

10.50

Two inner wires

109

Geoalloy drill pipe

φ50*1.5M

DZ50Taper

11.60

Friction welding at both ends

110

Geoalloy drill pipe

φ50*1.5M

45#Taper

11.60

Friction welding at both ends

111

Geoalloy drill pipe

φ50*1.5M

45#Hexagon

11.50

Friction welding at both ends

112

Geoalloy drill pipe

φ50*1.5M

DZ50Hexagon

11.50

Friction welding at both ends

113

Geoalloy drill pipe

φ50*2.0M

45#Taper

15.00

Friction welding at both ends

114

Geoalloy drill pipe

φ50*2.0M

DZ50Taper

15.00

Friction welding at both ends

115

Geoalloy drill pipe

φ50*2.5M

45#Taper

18.50

Friction welding at both ends

116

Geoalloy drill pipe

φ50*2.5M

DZ50Taper

18.50

Friction welding at both ends

117

Geoalloy drill pipe

φ63.5*0.8M

R780Taper

9.10

Friction welding at both ends

118

Geoalloy drill pipe

φ63.5*0.8M

45#Taper

10.00

Friction welding at both ends

119

Geoalloy drill pipe

φ63.5*1.0M

R780Taper

11.50

Friction welding at both ends

120

Geoalloy drill pipe

φ63.5*1.0M

45#Taper

12.70

Friction welding at both ends

121

Geoalloy drill pipe

φ63.5*1.5M

R780Taper

16.40

Friction welding at both ends

122

Geoalloy drill pipe

φ63.5*1.5M

45#Taper

18.00

Friction welding at both ends

123

Geoalloy drill pipe

φ63.5*1.6M

R780Taper

17.00

Friction welding at both ends

124

Geoalloy drill pipe

φ63.5*1.6M

45#Taper

18.50

Friction welding at both ends

Related Products

Product message

Shandong Banghong Zhongchuang Intelligent Equipment Co., Ltd.

Address: West Huamei Road, Linqing Youth Office, Liaocheng City, Shandong Province

copyright © 2022 Shandong Banghong Zhongchuang Intelligent Equipment Co., Ltd.

+86-13508921191

+86-13508921191