Let the world fall in love with Banghong Zhongchuang, and let Chinese drilling tools go to the world!

View the official account

Φ89Geological alloy cable drill pipe

所属分类:

Φ89Geological alloy cable drill pipe

关键词:

Specifications

Material code

Connection method

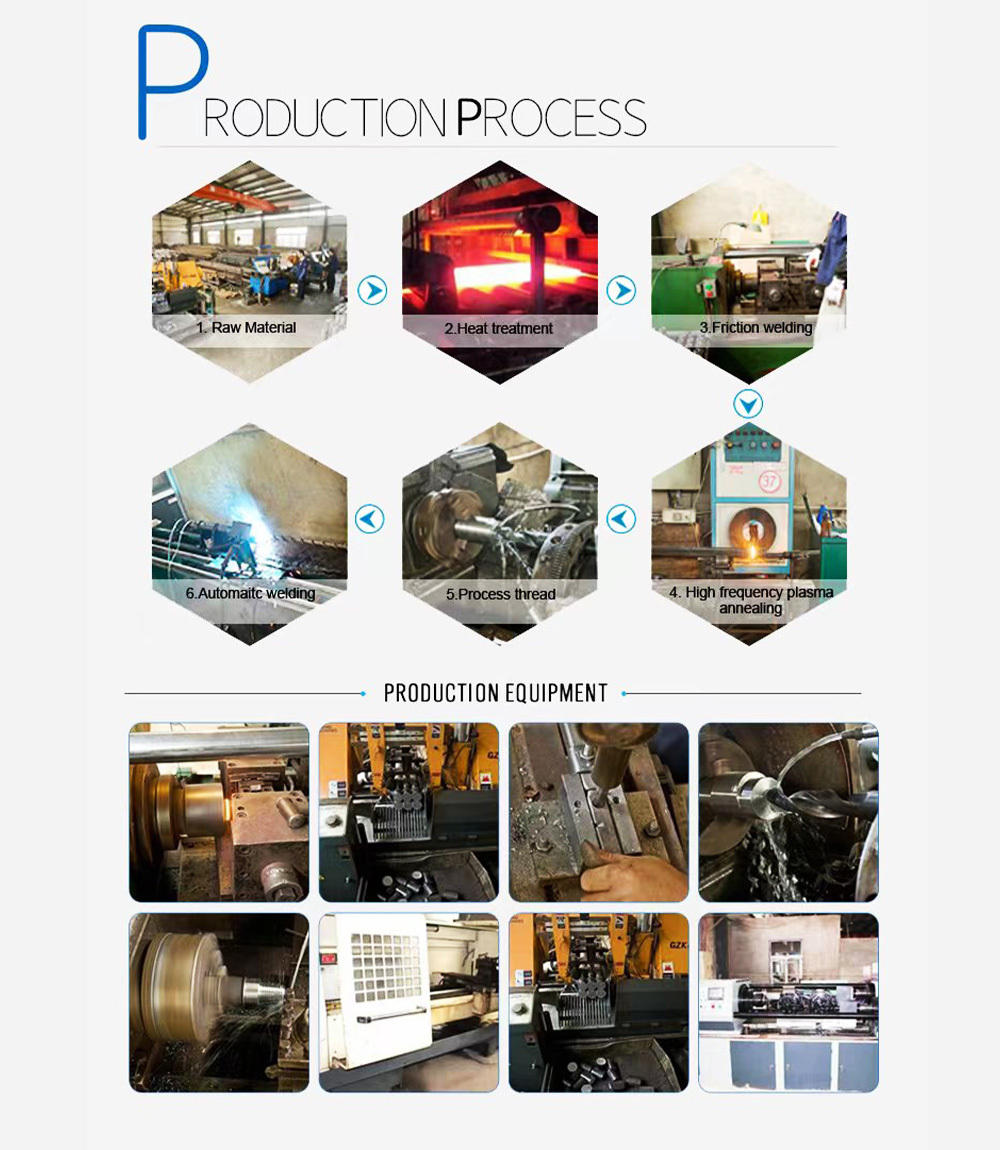

Production Process

Scope of application

咨询热线:

- Product Description

- Instructions for use

- Applications

- Product parameters

-

- Commodity name: Φ89Geological alloy cable drill pipe

- Specifications: Φ89

- Material code: -

- Connection method: -

- Production Process: -

- Scope of application: Φ89Geological alloy cable drill pipes are generally required to be constructed in complete coal seams (f≥1) or stable rock formations (f≤6); they are mainly used for near-horizontal and long-distance gas drainage drilling and water exploration and drainag

Φ89Geological alloy cable drill pipe

The center cable drill pipe and the directional drilling rig are widely used in drilling engineering, such as drilling inclination correction; making up the rock and ore core; bypassing the accident hole section or complex hole section, avoiding ground obstacles, one hole with multiple branches, Exploration of steeply inclined ore bodies, coal seam gas drainage or coalbed methane mining, hydrogeological and engineering geological exploration in specific locations of mine shafts, excavation and laying of underground pipelines, etc. However, as far as coal mines are concerned, the application in the field of gas prevention and development is also multi-faceted, such as regional gas pre-drainage in local coal seams, excavation pre-drainage, gas drainage in goafs, non-mining seam gas pre-drainage, etc. It can greatly reduce the investment cost of gas prevention and development, and can also improve the drainage concentration, providing quality assurance for the utilization of gas.

Product introduction

The center cable drill pipe is also called directional drill pipe or MWD drill pipe. It is an important drilling tool for directional drilling and geologically controlled drilling in underground tunnels in coal mines, and plays an important role in coal seam measurement and gas extraction construction in coal mines.

Directional drilling technology is one of the best drilling methods in the world. It is a drilling method that uses the natural bending law of the borehole or uses artificial deflection tools to extend the borehole to the predetermined target according to the design requirements. Drill to the specified position according to the pre-designed drilling path.

The center cable drill pipe is the signal transmission device used in directional drilling, and it is also an important part to ensure the smooth implementation of directional drilling. Due to the harsh operating environment of the drill pipe, there are higher requirements for the quality of signal transmission and stable performance of the rod body.Product advantages

The manufacturing process of drill pipe is divided into joint thickening integrated type and friction welding type. The joint adopts special heat treatment process, which has high strength and hardness. The thread adopts special tooth type to ensure the safety and reliability of the connection. The drill pipe body adopts G105 conforming to API standard. , S135 oil pipe is produced, through the overall quenching and tempering treatment, it can improve the overall mechanical properties and prolong the service life. The cable joints are custom-made with imported PPR (100) grade new raw materials, the mold precision is high, and the sealing effect is higher than similar products. Communication The cables are imported special conductor copper alloy cables, which can cope with various extreme use environments. Precise material selection not only ensures stable quality but also prolongs the service life of the drill pipe.

Scope of application

The central cable drill pipe is generally required to be constructed in a complete coal seam (f≥1) or stable rock layer (f≤6); it is mainly used for the construction of near-horizontal and long-distance gas drainage holes, water exploration and drainage holes in coal mines, and also It can be used for directional drilling construction such as ground and tunnel near-horizontal engineering drilling. Mainly used in coal mine directional drilling, underground rotary drilling and other geologically controlled directional drilling conditions, as well as gas drainage, gas seam development, emergency rescue, detection and discharge of goaf water and geological structures, etc.

-

Product Advantage Product Advantage

Drill pipe manufacturing process is divided into joint thickening integrated type and friction welding type. The joint adopts special heat treatment process and has high strength and hardness, the thread adopts a special thread to ensure the safety and reliability of the connection. The drill pipe body is produced with G105 and S135 oil pipes that meet API standards. Imported PPR (100) grade new raw materials are custom processed, with high mold precision, and the sealing effect is higher than that of similar products. The communication cable is an imported special conductor copper alloy cable, which can cope with various extreme use environments. Precise material selection not only ensures stable quality but also prolongs the service life of the drill pipe.

-

The special-shaped multi-edge grooved cable drill pipe is generally required to be constructed in a complete coal seam (f≥1) or stable rock layer (f≤6); it is mainly used for near-horizontal and long-distance gas drainage drilling, exploration and water drilling in coal mines It can also be used for directional drilling construction such as drilling on the ground and near-horizontal engineering in tunnels. Mainly used in coal mine directional drilling, underground rotary drilling and other geologically controlled directional drilling conditions, as well as gas drainage, gas seam development, emergency rescue, detection and discharge of goaf water and geological structures, etc.

-

Drill pipe diameter

Length

Insulation resistance

Conductor resistance

Water pressure

Drill pipe helix

Steel grade

Ф70mm

1500-3000mm

≥500MΩ

0.5-1.5Ω

7-10Mpa

Flat type, body milling type

G105, S135

Ф73mm

1500-3000mm

≥500MΩ

0.5-1.5Ω

7-10Mpa

Flat type, body milling type

G105, S135

Ф76mm

1500-3000mm

≥500MΩ

0.5-1.5Ω

7-10Mpa

Flat type, body milling type

G105, S135

Ф89mm

1500-3000mm

≥500MΩ

0.5-1.5Ω

7-10Mpa

Flat type, body milling type

G105, S135

Related Products

Product message

Shandong Banghong Zhongchuang Intelligent Equipment Co., Ltd.

Address: West Huamei Road, Linqing Youth Office, Liaocheng City, Shandong Province

copyright © 2022 Shandong Banghong Zhongchuang Intelligent Equipment Co., Ltd.

+86-13508921191

+86-13508921191