Let the world fall in love with Banghong Zhongchuang, and let Chinese drilling tools go to the world!

View the official account

φ28-8 coal drill bit

所属分类:

φ28-8 coal drill bit

关键词:

Specifications

Material code

Connection method

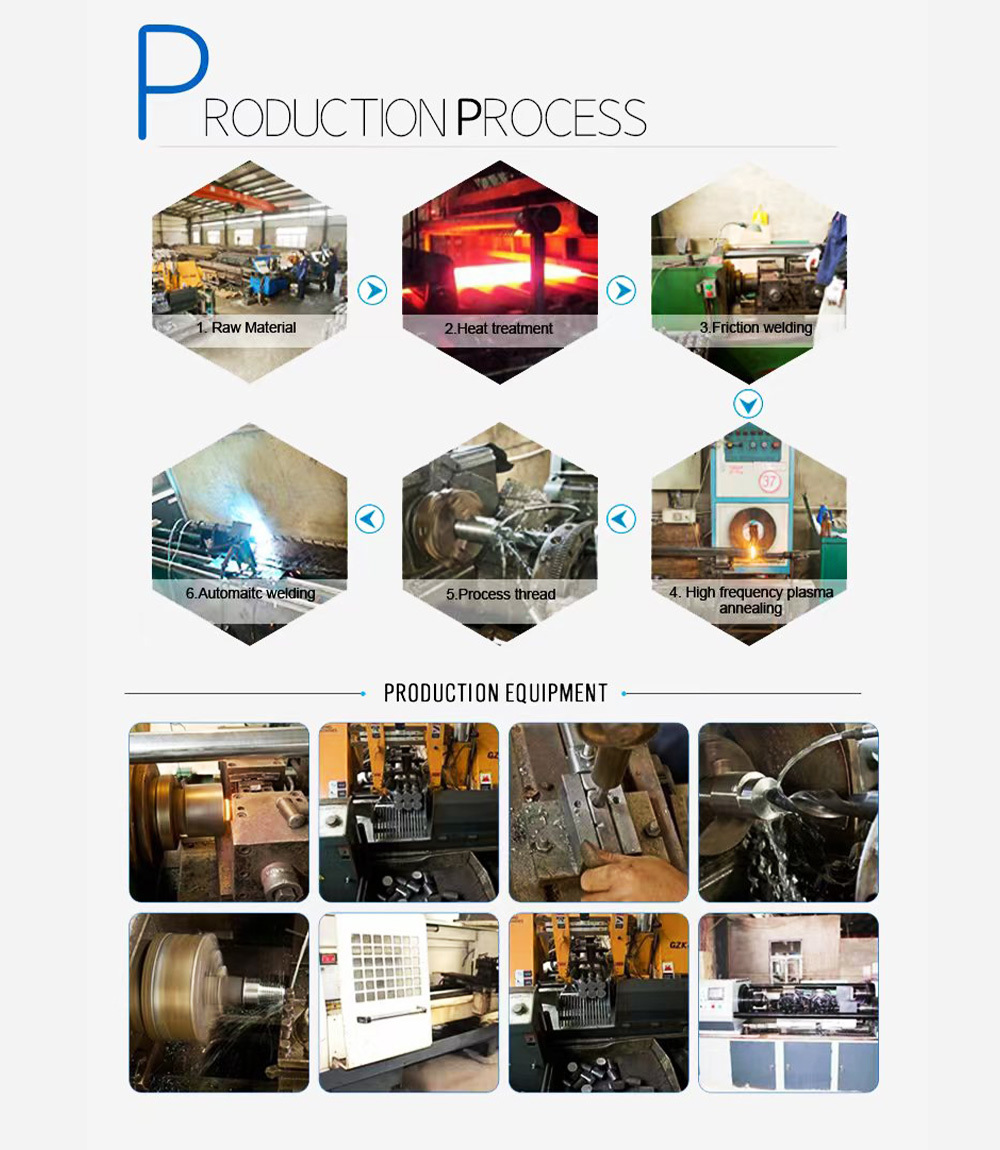

Production Process

Scope of application

咨询热线:

- Product Description

- Instructions for use

- Applications

- Product parameters

-

- Commodity name: φ28-8 coal drill bit

- Specifications: φ28-8

- Material code: -

- Connection method: -

- Production Process: -

- Scope of application: The rock drilling bit products produced by our company are widely used in various regions at home and abroad. The main domestic application areas are: China Coal Group, Longmei Group, Shenmei Group, Fengfeng Coal Industry, Kailuan Coal Industry, Lu'an Coa

φ28-8 coal drill bit

Carbide drill

Alias: coal drill bit, coal rock drill bit

Carbide coal and rock drill bits series, complete varieties. The drill body adopts a variety of production and processing processes such as precision casting, precision forging and medium carbon alloy steel cutting to meet the needs of different drill types and different drilling conditions.

Product Usage

Application field: widely used in drilling and reaming of soft rocks such as coal mines and gypsum mines.

Product Description

1. When working in different rock formations, choose different types of drill bits, axial pressure and rotational speed according to the hardness of the lithology.

2. When the drilling rig is perforating, it must follow the principle of matching the three elements of perforation (wind pressure, axial pressure, speed) and the parameters recommended by the drill sample.

3. Before the cemented carbide coal and rock drill bit goes down the well, please check the appearance of all parts, and verify whether the end face of the drill bit thread is consistent with the factory number on the drill bit packing box and qualification certificate; whether the surface of the drill bit tooth palm is pasted with cutting-edge trademark marks to prevent counterfeiting .

4. The drill bit should be stored reasonably on the drilling rig to prevent dust and other debris from entering the drill bit.

5. When replacing the drill bit, it is necessary to ensure that there is no dust inside the drilling tool, the air outlet is unobstructed, the thread is oiled, and the drill bit can be used after connecting the drill bit by means of lifting and rotating.

6. Before replacing the new drill bit, carefully check whether the thread and teeth are in good condition.

7. When the new drill bit is drilled, it should be run at low axial pressure and low speed for 20-30 minutes, and then gradually increase to normal axial pressure for use.

8. When opening a new hole with a new drill, pay attention to removing the debris around the hole (rocks, scrap metal, etc.), while rotating, ventilate slowly and close to the surface to prevent drilling and impact damage to the drill.

9. When working in soft rock formations, and replacing the drill bit in the middle, it is necessary to strictly check whether the alloy teeth on the palm and back of the old drill bit and the rollers have fallen off to the bottom of the hole. Use a new drill bit.

10. When the drilling rig is stopped, the drilling tool cannot be parked in the hole with water to prevent the rock slag and water from flowing backwards, entering the bearing and damaging the drill bit.

11. When there are cracks in the rock or rock cracks caused by blasting and goaf operations, reduce the axial pressure and rotation speed to prevent the teeth from breaking.

12. When the drilling tool is in the hole, it is strictly forbidden to reverse it to prevent the drill bit from falling into the well.

13. When the drill bit is in the hole and the air compressor suddenly stops working, the slag can easily enter the drill bit, so it is strictly forbidden to rotate for a long time, which will lead to bearing wear, repeated crushing of the slag (or stuck drill), and accelerated wear of the drill bit.

14. During the normal perforation operation, there should be no serious air leakage in the main air path of the air compressor to ensure sufficient air volume and air pressure and prolong the service life of the drill bit.

15. The rod stabilizer should be replaced regularly to ensure the stability of the drill rod and the normal operation of the drill bit.

16. It is strictly forbidden to use curved drill rods to avoid uneven force on the three teeth of the drill bit and accelerate the damage of the drill bit.

17. The drill should be stored in moisture-proof and ventilated. During the handling process, it is strictly forbidden to bump the cones and threads.

-

Product Description:

1. When working in different rock formations, choose different types of drill bits, axial pressure and rotational speed according to the hardness of the lithology .

2. When the drilling rig is perforating, it must follow the principle of matching the three elements of perforation (wind pressure, axial pressure, speed) and the parameters recommended by the drill sample.

3. Before the cemented carbide coal and rock drill bit goes down the well, please check the appearance of all parts, and verify whether the end face of the drill bit thread is consistent with the factory number on the drill bit packing box and qualification certificate; whether the surface of the drill bit tooth palm is pasted with cutting-edge trademark marks to prevent counterfeiting .

4. The drill bit should be stored reasonably on the drilling rig to prevent dust and other debris from entering the drill bit.

5. When replacing the drill bit, it is necessary to ensure that there is no dust inside the drilling tool, the air outlet is unobstructed, the thread is oiled, and the drill bit can be used after connecting the drill bit by means of lifting and rotating.

6. Before replacing the new drill bit, carefully check whether the thread and teeth are in good condition.

7. When the new drill bit is drilled, it should be run at low axial pressure and low speed for 20-30 minutes, and then gradually increase to normal axial pressure for use.

8. When opening a new hole with a new drill, pay attention to removing the debris around the hole (rocks, scrap metal, etc.), while rotating, ventilate slowly and close to the surface to prevent drilling and impact damage to the drill.

9. When working in soft rock formations, and replacing the drill bit in the middle, it is necessary to strictly check whether the alloy teeth on the palm and back of the old drill bit and the rollers have fallen off to the bottom of the hole. Use a new drill bit.

10. When the drilling rig is stopped, the drilling tool cannot be parked in the hole with water to prevent the rock slag and water from flowing backwards, entering the bearing and damaging the drill bit.

11. When there are cracks in the rock or rock cracks caused by blasting and goaf operations, reduce the axial pressure and rotation speed to prevent the teeth from breaking.

12. When the drilling tool is in the hole, it is strictly forbidden to reverse it to prevent the drill bit from falling into the well.

13. When the drill bit is in the hole and the air compressor suddenly stops working, the slag can easily enter the drill bit, so it is strictly forbidden to rotate for a long time, which will lead to bearing wear, repeated crushing of the slag (or stuck drill), and accelerated wear of the drill bit.

14. During the normal perforation operation, there should be no serious air leakage in the main air path of the air compressor to ensure sufficient air volume and air pressure and prolong the service life of the drill bit.

15. The rod stabilizer should be replaced regularly to ensure the stability of the drill rod and the normal operation of the drill bit.

16. It is strictly forbidden to use curved drill rods to avoid uneven force on the three teeth of the drill bit and accelerate the damage of the drill bit.

17. The drill should be stored in moisture-proof and ventilated. During the handling process, it is strictly forbidden to bump the cones and threads. -

The cemented carbide drill bits produced by our company are widely used in various regions at home and abroad. The main domestic application areas are: China Coal Group, Longmei Group, Shenmei Group, Fengfeng Coal Industry, Kailuan Coal Industry, Lu'an Coal Industry Industry, Yangmei Group, Jinmei Group, Xishan Coal and Electricity, Fenxi Coal Industry, Datun Coal Industry, Xinji Energy, etc.; the main use areas in foreign countries: Russia, Australia, Southeast Asia and Northern Europe.

-

Product parameters

Production process: precision casting, precision forging and medium carbon alloy steel cutting, etc.

structure: integralline number Specification Model mm Blade form Structure Diameter Regular connection size 1

Ф27

M12/Φ8

M14×1.5

2

overall 2

Ф28

M12/Φ8

F12×12

2

overall 3

Ф30

M12/Φ8

F12×12

2

overall 4

Ф32

M14×1.5/Φ8

F12×12

2

overall 5

Ф34

M14×1.5/Φ8

F12×12

2

overall 6

Ф36

M14×1.5/Φ8

F12×12

2

overall 7

Ф38

T24×5/Φ12

F14×14

2-3

overall 8

Ф42

T24×5/Φ12

F13-14

2-3

overall 9

Ф45

T24×5/Φ12

F13-18

2-3

overall 10

Ф55

T24×5/Φ12

F13-18

4

two-level combination 11

Φ65

T24×5

F13-18

4-5

two-level combination 12

Φ75

T33×4.23

F13-18

4-5

two-level combination 13

Φ76

T33×4.23

F18-24

4-5

two-level combination 14

Φ82

T42×5.08

F18-24

4-5

two-level combination 15

Φ85

T42×5.08

F18-24

4-5

two-level combination 16

Φ89

T42×5.08

F24-32

5-7

three-level combination 17

Φ95

T55×5.08

F24-32

5-7

three-level combination 18

Φ110

T55×5.08

B35-45

5-7

three-level combination 19

Φ125

T55×5.08

B35-45

5-12

four-level combination 20

Φ135

T55×5.08

B35-45

5-12

four-level combination

Related Products

Product message

Shandong Banghong Zhongchuang Intelligent Equipment Co., Ltd.

Address: West Huamei Road, Linqing Youth Office, Liaocheng City, Shandong Province

copyright © 2022 Shandong Banghong Zhongchuang Intelligent Equipment Co., Ltd.

+86-13508921191

+86-13508921191