Let the world fall in love with Banghong Zhongchuang, and let Chinese drilling tools go to the world!

View the official account

B22-1200 Anchor cable drill pipe

所属分类:

B22-1200 Anchor cable drill pipe

关键词:

Specifications

Material code

Connection method

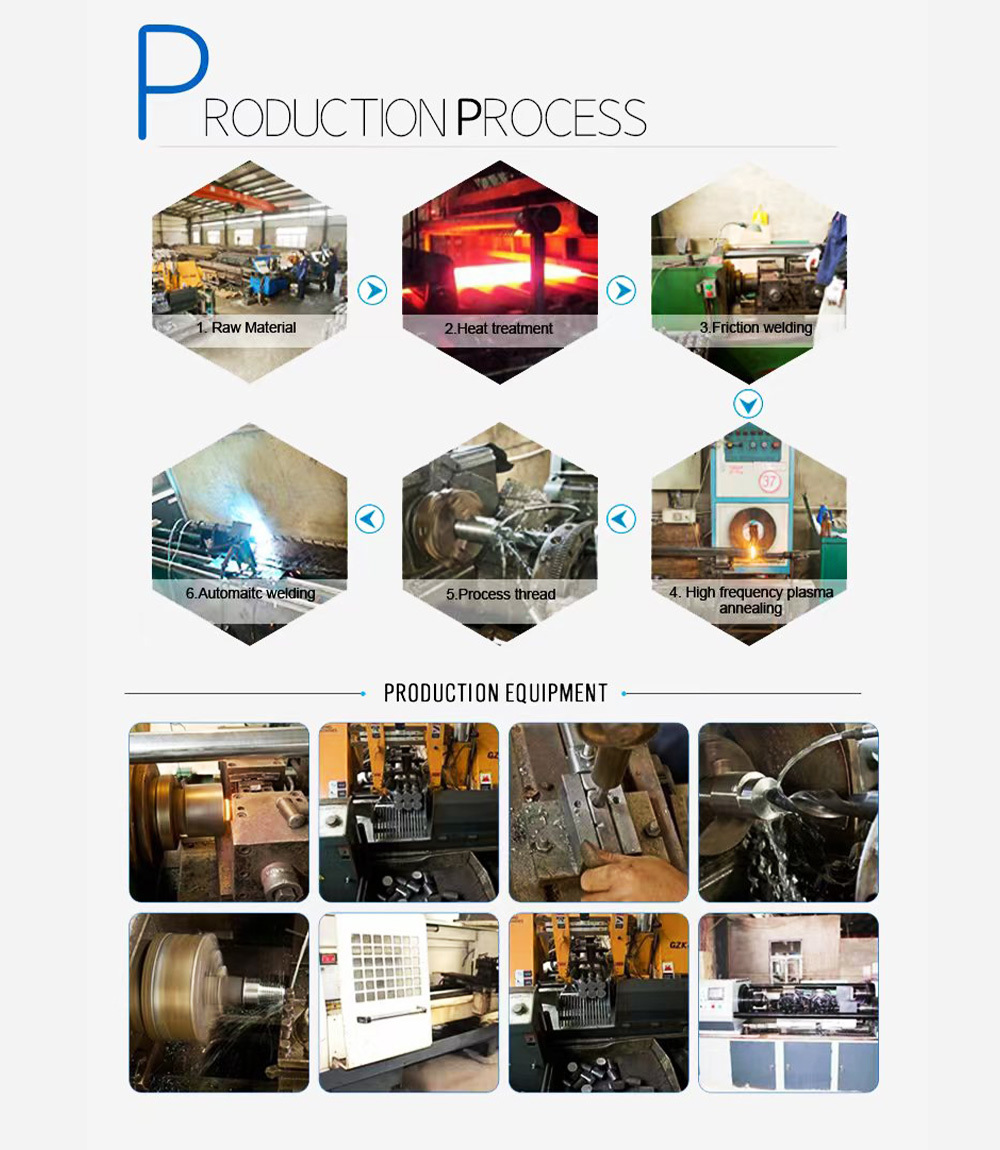

Production Process

Scope of application

咨询热线:

- Product Description

- Instructions for use

- Applications

- Product parameters

-

- Commodity name: B22-1200 Anchor cable drill pipe

- Specifications: B22-1200

- Material code: -

- Connection method: -

- Production Process: -

- Scope of application: The rock drilling pipe products produced by our company are widely used in various regions at home and abroad. The main domestic application areas are: China Coal Group, Longmei Group, Shenmei Group, Fengfeng Coal Industry, Kailuan Coal Industry, Lu'an Co

B22-1200 Anchor cable drill pipe

Rock drill pipe

Alias: Drill, Pneumatic drill pipe, anchor cable auger pipeOur company produces anchor drill pipe, Pneumatic drill rods, flat-shaped finished drills, cross-shaped finished drills and other products are made of 55SiMnMo and 90CrMo high-quality hexagonal hollow alloy steel as raw materials. The use of CNC automation equipment to process and form ensures stable and reliable product quality.

B19 drill rod, also known as B19 anchor rod, is used on rock bolt drilling rigs. Equipped with an anchor drill bit. The length of B19 anchor cable drill pipe is 1m/root, 1.5m/root, 1.2/m, and can also be customized according to needs. The drill pipe is made of 60Si2Mn high-quality hexagonal hollow alloy steel by high pressure forging, and the whole is quenched and tempered in vacuum. Strong bending resistance, sturdy and durable, easy to disassemble and operate.

Product Parameters:Product ParametersLength:0.5~3m

Connection type: Threaded link

A table of common specifications and performance parameters of anchor rod/bolt rod:Line numbers

Specification in mm

Main purpose

Notes

diameter

length

Thread size

1

B19

500~3000

T16×6-M14

Drilling anchor holes

Single root use

2

B19

500~3000

T16×6-T16

Drilling hole for anchor cable

connector connection

3

B19

500~3000

T18×6-T18

Drilling hole for anchor cable

connector connection

4

B22

500~6000

T19×6-M16

Drilling anchor holes

Single root use

5

B22

500~6000

T19×6-T19

Drilling hole for anchor cable

connector connection

6

B22

500~6000

T20×6-T20

Drilling hole for anchor cable

connector connection

7

B25

500~6000

T22×6-M18

Drilling anchor holes

Single root use

8

B25

500~6000

T22×6-T22

Drilling hole for anchor cable

connector connection

9

B25

500~6000

T24×6-T24

Drilling hole for anchor cable

connector connections

Product Usage

Application:Products are widely used in mine roadway support drilling, mine rock drilling, coal mine rock roadway, bridge tunnel excavation and other engineering construction.

Maintenance Instructions

1. The drill pipe should be regularly maintained and maintained, according to the use environment and airHumidity determines the maintenance cycle, and anti-rust oiling and dust-proof treatment are carried out on a regular basis.

2. The use of the drill pipe should be within the rated drilling distance of the drilling rig, and the matching drill pipe should be selected according to the technical parameters of the drilling distance and the model of the drilling rig.

3. In the construction of mine roadway support drilling, mine rock drilling, coal mine rock roadway, bridge tunnel excavation and other engineering construction or other special environmental operations, it is necessary to determine the reasonable drilling depth according to the actual material, physical properties and parameters of the drill pipe. .

4. When the drill pipe and the drill bit are used together, the drill bit should be larger than the diameter of the drill pipe under normal circumstances, and the conditions of the drill rig and the drill pipe should always be paid attention to during the drilling process. If there are phenomena such as sticking or locking, the drilling should be stopped immediately or drilled back slowly to ensure that the drill pipe is not bent and deformed.

5. When the drill pipe is ventilated or watered, it should be determined that the drill pipe is tightly connected when drilling. When the drill pipe has seals, such as O-rings, pay attention to the use of the seals, and replace the seals in time when damage or corrosion occurs. After drilling is completed, maintenance and cleaning of the seals are performed.

6. When drilling, the drill pipe should be connected manually and correctly to ensure a tight fit. Do not use the drilling rig to drill directly to prevent damage to the drill pipe.

7. If the bending degree of the drill pipe exceeds the standard requirements or the thread is damaged after use, it should be scrapped in time or returned to the factory for repair.

8. According to the standard requirements, it should be ensured that the drilling depth of the drill pipe meets the relevant requirements of geological drilling to prevent the drill pipe from falling off due to the drilling depth reaching the limit of the use of the drill pipe.

9. When working in acid and alkali areas, attention should be paid to the corrosion effect on the drill pipe. When drilling is completed, the surface of the rod body should be cleaned with clean water in time to remove the corrosion layer.

10. The drill pipe should be stored in a dry place, and the bottom should be supported at multiple points. During long-term storage, the drill pipe should be regularly maintained.

11. The drill pipe shall not be used as a support platform for stacking heavy tails, and shall not be placed under the gravel, coal piles or scattered randomly.

12. Drill pipe maintenance After rust removal/dust cleaning, the protective cap should be buckled or boxed and sealed to ensure that the drill pipe is always new.

-

Product Usage

Application fields: The products are widely used in the construction of mine roadway support drilling, mine rock drilling, coal mine rock roadway, bridge tunnel excavation and other engineering construction.

Maintenance Instructions

1. The drill pipe should be maintained regularly. The maintenance cycle should be determined according to the use environment and air humidity, and the anti-rust oiling and dust-proof treatment should be carried out regularly.

2. The use of the drill pipe should be within the rated drilling distance of the drilling rig, and the matching drill pipe should be selected according to the technical parameters of the drilling distance and the model of the drilling rig.

3. In the construction of mine roadway support drilling, mine rock drilling, coal mine rock roadway, bridge tunnel excavation and other engineering construction or other special environmental operations, it is necessary to determine the reasonable drilling depth according to the actual material, physical properties and parameters of the drill pipe. .

4. When the drill pipe and the drill bit are used together, the drill bit should be larger than the diameter of the drill pipe under normal circumstances, and the conditions of the drill rig and the drill pipe should always be paid attention to during the drilling process. If there are phenomena such as sticking or locking, the drilling should be stopped immediately or drilled back slowly to ensure that the drill pipe is not bent and deformed.

5. When the drill pipe is ventilated or watered, it should be determined that the drill pipe is tightly connected when drilling. When the drill pipe has seals, such as O-rings, pay attention to the use of the seals, and replace the seals in time when damage or corrosion occurs. After drilling is completed, maintenance and cleaning of the seals are performed.

6. When drilling, the drill pipe should be connected manually and correctly to ensure a tight fit. Do not use the drilling rig to drill directly to prevent damage to the drill pipe.

7. If the bending degree of the drill pipe exceeds the standard requirements or the thread is damaged after use, it should be scrapped in time or returned to the factory for repair.

8. According to the standard requirements, it should be ensured that the drilling depth of the drill pipe meets the relevant requirements of geological drilling to prevent the drill pipe from falling off due to the drilling depth reaching the limit of the use of the drill pipe.

9. When working in acid and alkali areas, attention should be paid to the corrosion effect on the drill pipe. When drilling is completed, the surface of the rod body should be cleaned with clean water in time to remove the corrosion layer.

10. The drill pipe should be stored in a dry place, and the bottom should be supported at multiple points. During long-term storage, the drill pipe should be regularly maintained.

11. The drill pipe shall not be used as a support platform for stacking heavy tails, and shall not be placed under the gravel, coal piles or scattered randomly.

12. Drill pipe maintenance After rust removal/dust cleaning, the protective cap should be buckled or boxed and sealed to ensure that the drill pipe is always new. -

The rock drilling pipe products produced by our company are widely used in various regions at home and abroad. The main domestic application areas are: China Coal Group, Longmei Group, Shenmei Group, Fengfeng Coal Industry, Kailuan Coal Industry, Lu'an Coal Industry Industry, Yangmei Group, Jinmei Group, Xishan Coal and Electricity, Fenxi Coal Industry, Datun Coal Industry, Xinji Energy, etc.; the main use areas in foreign countries: Russia, Australia, Southeast Asia and Northern Europe.

-

Product parameters

Related Products

Product message

Shandong Banghong Zhongchuang Intelligent Equipment Co., Ltd.

Address: West Huamei Road, Linqing Youth Office, Liaocheng City, Shandong Province

copyright © 2022 Shandong Banghong Zhongchuang Intelligent Equipment Co., Ltd.

+86-13508921191

+86-13508921191